Keep Your Pipelines and Infrastructure Operational

When your pipelines and infrastructure are operational, your company can thrive. Your product can move from point A to point B, and business continues on as it should. But it’s easy to take your infrastructure for granted.

If the system wasn’t constructed properly, or if there’s been some wear on the infrastructure, corrosion can set in. This can result in disruptions and downtime, and substantial financial losses.

Dreiym Engineering, located in Houston, can help you ensure that your pipelines and other infrastructure are healthy and operational. Our cathodic protection and professional corrosion engineering consulting services can keep your operations running smoothly so that you can worry about more pressing matters.

We are a Professional Corrosion Engineering Firm

Whether you are looking to invest in new infrastructure or caring for the system that you currently use, we can help. Take a look at some of our cathodic protection services that can benefit your company.

Cathodic_Protection_Survey

Cathodic_Protection_Survey Trust it to Us

We spend Professional Engineers and Cathodic Protection Specialists to personally oversee each field inspection. We know its right so you know its right.

ultrasonic_thickness_measurement

ultrasonic_thickness_measurement Engineers you can Rely On

Nothing can replace an trained and experianced professional engineer with their eyes on the system they are troubleshooting.

cp-surveys

cp-surveys Soil Corrosivity Analysis

- Measuring soil resistivity, pH, sulfate and chloride content, bacteria, Redox Potential and indicators of anaerobic conditions.

- Determination of the corrosivity of the environment and make recommendations on the type of corrosion prevention techniques to utilize.

- Using certified labs, soil samples are analyzed for various constituents that contribute to a corrosive environment.

cathodic-protection-design

cathodic-protection-design Structure-to-Electrolyte Potential Surveys

- Measuring the performance of existing corrosion prevention systems to determine compliance with regulatory requirements.

- AC/DC Interference analysis. Performing troubleshooting techniques to determine if interference conditions exist and make recommendations to mitigate the effects.

- DCVG & ACVG, Close Interval Surveys, Interrupted Potentials, and More.

- Dreiym only uses calibrated instruments to ensure accuracy.

Structure-to-soil-potential-min

Structure-to-soil-potential-min Commissioning & Acceptance Testing

- Performing initial energization tests on newly installed corrosion prevention systems.

- Structure/coating non-destructive integrity inspection and evaluation.

- Detailed reports on the status of your corrosion control systems, including detailed solutions to any issues.

interference1

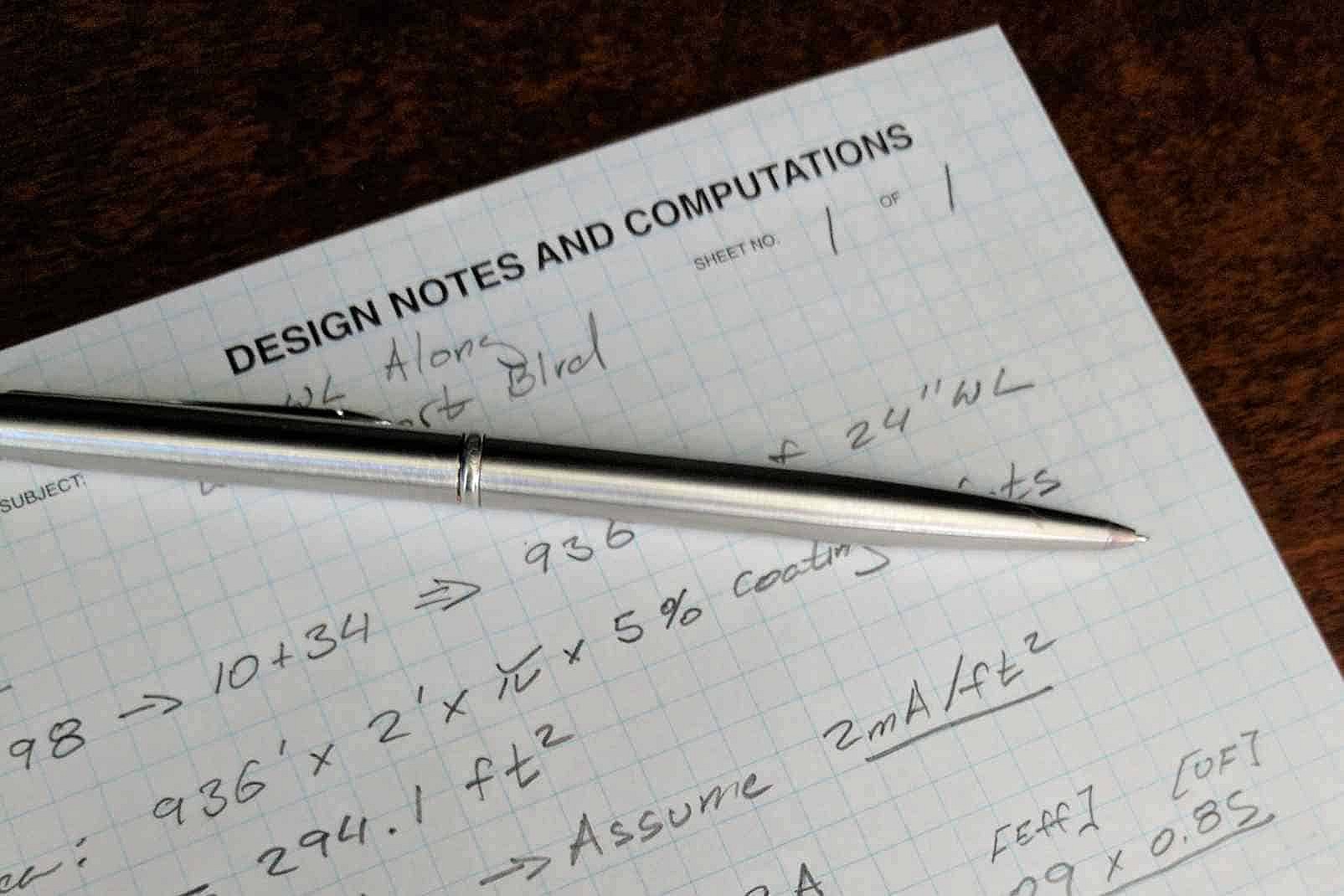

interference1 Design of Corrosion Prevention Systems

- Design of Corrosion Prevention Systems, Details, Specification

- Compliant with the latest regulatory and industry standards (NACE International/ISO/USEPA/USDOT)

- Design Engineering Oversight of installation and construction activities.

- Designs are performed by NACE Certified CP4s (Cathodic Protection Specialists) with Professional Engineering Licenses in the local jurisdiction.

Go with Experience

When it comes to a fully functional infrastructure, don’t leave your business’s livelihood to chance. The effects of corrosion can be catastrophic.

We can ensure the health of your company’s infrastructure – no matter how old or new. Our team consists of experienced professional corrosion engineers. Chances are we’ve seen a job just like yours.

If you have further questions or would like to discuss your project, contact us today!