Causes of Stray-Current Corrosion and How To Prevent It

Corrosion affects metals and infrastructure using metals. It can hold devastating consequences when not properly addressed and actively prevented. There are multiple different types of corrosion that can affect metals. Each is unique in its causes, prevention methods, and effects on the metal structures. Stray-current corrosion is a type of corrosion that is dynamic and transient. It’s connected to electricity and can even be caused by traditional corrosion prevention methods. While this may make it seem unavoidable, its disastrous results shouldn’t be accepted or ignored. Preventing stray-current corrosion is key to maintaining a safe and robust metal structure. Discover the causes of stray-current corrosion and how to prevent it.

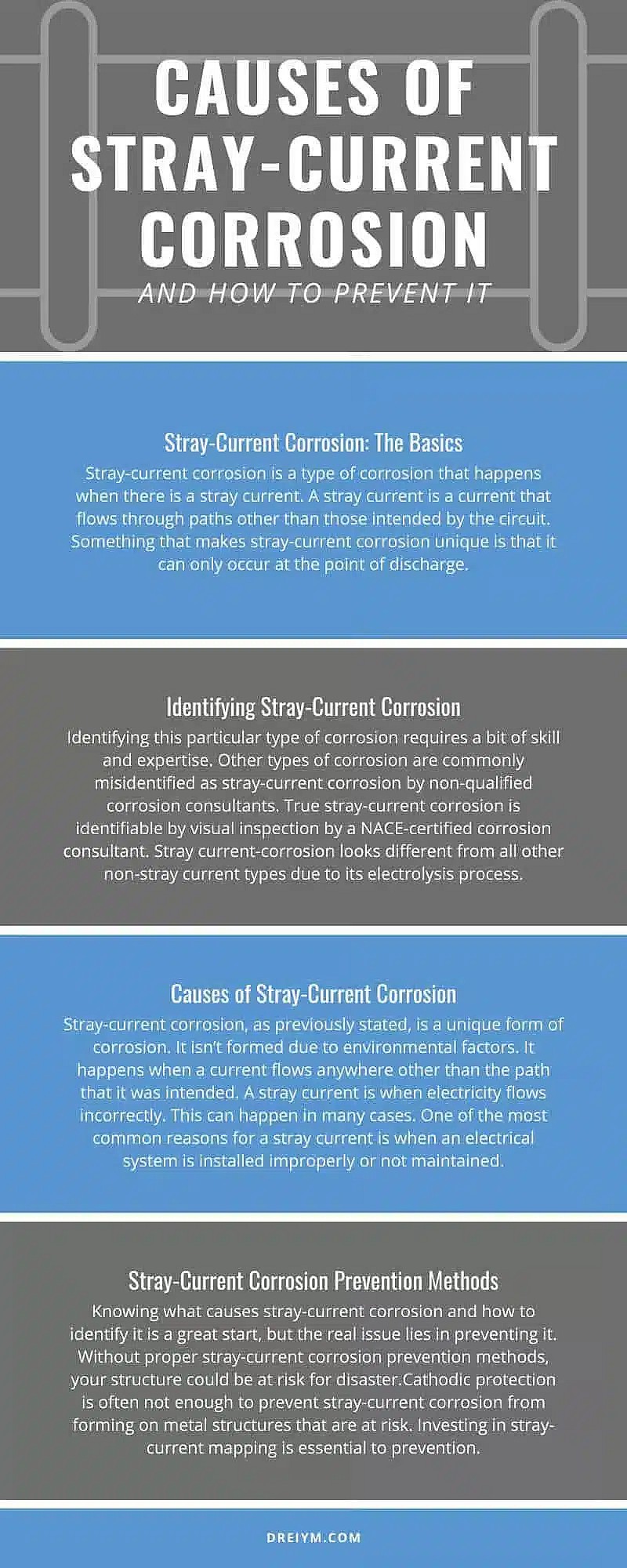

Stray-Current Corrosion: The Basics

Stray-current corrosion is a type of corrosion that happens when there is a stray current. A stray current is a current that flows through paths other than those intended by the circuit. Something that makes stray-current corrosion unique is that it can only occur at the point of discharge. Discover more essential facts about stray-current corrosion below.

- It’s not natural corrosion because an external and independent factor, unaffected by the environment, can cause it.

- Potential differences with the less conductive environment appear when a stray current flows through, which creates a corrosion cell.

- It can affect the service life and safety of pipelines and other metal structures.

- It is basically electrochemical corrosion.

- Some of the main factors contributing to the formation of stray-current corrosion are high electrical resistance, poor installation of metals into the earth, and voltage drops caused by substations that are too widely spaced.

Stray-current corrosion is a relatively common form of corrosion that is known to be devastating when not promptly addressed to metal applications—especially railways and pipelines.

Identifying Stray-Current Corrosion

Identifying this particular type of corrosion requires a bit of skill and expertise. Other types of corrosion are commonly misidentified as stray-current corrosion by non-qualified corrosion consultants. True stray-current corrosion is identifiable by visual inspection by a NACE-certified corrosion consultant.

Stray current-corrosion looks different from all other non-stray current types due to its electrolysis process. Environmental factors are not relevant even though they tend to be prominent in other kinds of corrosion.

Any buried metal structure is vulnerable to stray-current corrosion. It most commonly affects railways, pipelines, storage tanks, and other large metal structures.

Stray-current corrosion is often mistaken for galvanic corrosion. It is vastly different from galvanic corrosion in that it’s corrosion between two dissimilar metals, while stray current is unaffected by environmental corrosion and can cause far more significant damage.

Causes of Stray-Current Corrosion

Stray-current corrosion, as previously stated, is a unique form of corrosion. It isn’t formed due to environmental factors. It happens when a current flows anywhere other than the path that it was intended.

A stray current is when electricity flows incorrectly. This can happen in many cases. One of the most common reasons for a stray current is when an electrical system is installed improperly or not maintained. There are many things that could potentially cause an electrical current to stray off its intended path. Below are the most common sources of a current straying:

- Cathodic protection corrosion prevention systems

- Grounded direct currents distributing power

- Rapid transit systems that are electrically operated

- Electrical welding equipment

Electricity is a vital part of life and is something people rely on every day. It’s something that can also experience issues, disruptions, and more. Stray currents are just one of many dangerous things that can happen when electric systems go awry. Partnering with an expert and NACE-certified corrosion consultant and electrical engineering consultant can save businesses from experiencing a wide array of disasters and costs due to electrical failures and corrosion.

Stray-Current Corrosion Prevention Methods

Knowing what causes stray-current corrosion and how to identify it is a great start, but the real issue lies in preventing it. Without proper stray-current corrosion prevention methods, your structure could be at risk for disaster.

Cathodic protection is often not enough to prevent stray-current corrosion from forming on metal structures that are at risk. Investing in stray-current mapping is essential to prevention.

Stray-current mapping is a safe way to plot the path of your stray current. Knowing the course of your stray current and having a robust cathodic protection system that is regularly monitored will help prevent issues arise when stray-current corrosion cells form.

Cathodic protection can cause stray currents to form, leading to corrosion. Cathodic protection is designed to protect structures from corrosion, but it can actually lead to stray-current corrosion. It must be monitored and evaluated by certified corrosion consultants for the best results.

Stray-current corrosion is just one of many different kinds of corrosion that could affect your metal application. It’s imperative that you are vigilant in your efforts to prevent and predict corrosion. Corrosion can be devastating to your facilities, infrastructure, and other metal applications. It needs to be addressed and controlled. Contact Dreiym Engineering today for more information about our corrosion prevention plans. We offer a wide array of services, including gas pipeline cathodic protection systems. Pipelines are susceptible to corrosion and the consequences can be devastating. Allow our team of certified engineers to identify weak points and outline prevention steps to protect your pipeline or other structure from disastrous run-ins with corrosion.

At Dreiym Engineering, we prioritize your structure’s safety. We are experienced in cathodic protection system design, pipeline and tank analysis, soil corrosivity analysis, corrosion control design, and much more. Our corrosion consultants are NACE certified, so you can rest easy knowing your systems are protected by experts in the field of safe and cost-effective corrosion prevention. Contact us today for a free quote on our services and to learn more about what our consultants can do for your systems. Understanding the causes and how to prevent stray-current corrosion is essential to the structural health of pipelines, railways, and many other metal structures and infrastructures.