Pipeline Safety: What You Can Do To Improve It

When you invest in a building, whether that be starting one from scratch or renovating a pre-existing structure, you should always put your money toward reliable processes and materials for the most cost-effective outcome. One major aspect of infrastructure that can hinder a building’s structural integrity is pipeline damage. There are a number of reasons for pipeline damage to occur. When it happens, the safety of your staff, building, and company’s reputation are all put at risk. To avoid the costly repercussions of pipeline hindrance, review Dreiym Engineering’s guide to pipeline safety and what you can do to improve it.

What Causes Pipeline Damage?

There are many different reasons why a pipeline may burst or slowly break. Let’s first look at various company oversights, environmental factors, and other occurrences that may put your building at risk of insufficient pipelines.

Corrosion

Corrosion is one of the main reasons that your building’s pipeline quality may suffer. There are various forms of corrosion that metal pipelines are susceptible to, which we’ll discuss below briefly.

Pitting Corrosion

With pitting corrosion, the corrosion focuses itself on a pipeline’s weak spot, creating a cavity or hole. Corrosion pits on pipelines are caused by localized chemical or mechanical damage to protective film, improper corrosion prevention materials, and the presence of non-metals on the pipeline.

Uniform Corrosion

As the name indicates, uniform corrosion occurs all over the metal surface and the corrosion proceeds at a uniform rate. Exposure to incompatible soil, natural waters, and open atmospheres can cause this type of corrosion.

Galvanic Corrosion

When two dissimilar metals encounter one another in the presence of water, galvanic corrosion occurs. Galvanic corrosion is also known as dissimilar metal corrosion.

Crevice Corrosion

As you may guess, crevice corrosion takes place at, or adjacent to, the gap or crevice between two joined metal surfaces.

Microbiologically-Influenced Corrosion

Microbiologically influenced corrosion (MIC) is caused by microorganisms living on the pipeline’s surface. Microorganisms do not cause corrosion themselves, but their presence and activity speed up corrosive reactions.

Metal Fatigue

Metal fatigue causes any cracks within the pipeline to exacerbate with every loading process. When damage from metal fatigue occurs, it typically spreads little by little until an explosion or intense pipeline spill happens.

Improper Repair, Replacement, and Maintenance

Maintenance oversight is an unfortunate leading cause of pipeline damage and hazards. Companies that refuse to upkeep the quality of their pipeline systems typically run into both legal and financial troubles, as there are building safety regulations you must legally comply with as the owner of a building.

Chemical Damage

If not designed properly with the correct materials, some pipelines will not be able to withstand harsh chemicals. Hazardous chemicals can cause extreme wear and tear within a short period.

When planning your building’s structure and materials, consult with architectural professionals on what type of chemicals each building’s components will be able to endure. Knowing this information ahead of time can be greatly advantageous to choosing effective preventative measures for your building.

Faulty Pipes, Joints, and Valves

Sometimes, the faults are in the hardware. If a pipe, joint, or valve is too large or too small, your pipeline system is susceptible to failure. Thus, it’s especially important to double-check the dimensions of structural components when having consultants repair or replace building parts.

Natural Forces

Pipeline systems are highly vulnerable to natural forces. Lightning, wind, heavy precipitation, fire, humidity, temperature, soil, earth movement, and other external forces of nature are all influential to the pipeline’s integrity.

Nature’s effects on pipelines make humid locations especially challenging for ideal construction. You and your building consultants should always assess natural obstacles when planning for initial construction or renovations.

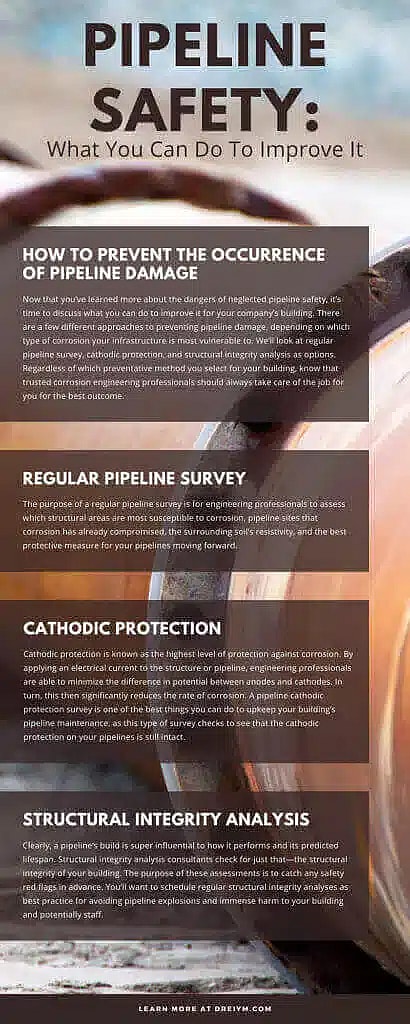

How To Prevent the Occurrence of Pipeline Damage

Now that you’ve learned more about the dangers of neglected pipeline safety, it’s time to discuss what you can do to improve it for your company’s building. There are a few different approaches to preventing pipeline damage, depending on which type of corrosion your infrastructure is most vulnerable to.

We’ll look at regular pipeline survey, cathodic protection, and structural integrity analysis as options. Regardless of which preventative method you select for your building, know that trusted corrosion engineering professionals should always take care of the job for you for the best outcome.

Regular Pipeline Survey

The purpose of a regular pipeline survey is for engineering professionals to assess which structural areas are most susceptible to corrosion, pipeline sites that corrosion has already compromised, the surrounding soil’s resistivity, and the best protective measure for your pipelines moving forward.

Cathodic Protection

Cathodic protection is known as the highest level of protection against corrosion. By applying an electrical current to the structure or pipeline, engineering professionals are able to minimize the difference in potential between anodes and cathodes. In turn, this then significantly reduces the rate of corrosion.

A pipeline cathodic protection survey is one of the best things you can do to upkeep your building’s pipeline maintenance, as this type of survey checks to see that the cathodic protection on your pipelines is still intact. If pipeline consultants find any faults in cathodic protection, they’ll then proceed with supplying your pipeline system with more protective products.

Structural Integrity Analysis

Clearly, a pipeline’s build is super influential to how it performs and its predicted lifespan. Structural integrity analysis consultants check for just that—the structural integrity of your building.

The purpose of these assessments is to catch any safety red flags in advance. You’ll want to schedule regular structural integrity analyses as best practice for avoiding pipeline explosions and immense harm to your building and potentially staff.

For Premier Corrosion Consultants

For a thorough pipeline analysis of any kind, call Dreiym Engineering, PLLC. Our team of electrical and corrosion engineering professionals is well-versed in methods to help assess your building and keep it safe. It’s important to entrust a reliable, knowledgeable team for the job to ensure the best evaluations and maintenance of your company’s building.

Keeping up with your building’s safety isn’t only vital to preventing costly damage repairs and replacements—it’s also critical to the health and safety of the public, your employees, and your finances. Contact us today for more information about our wide range of electrical and corrosion engineering services.