Why You Need a Site Walk-Down Inspection

For businesses that intend to keep their assets and employees safe, investments in preventative safety measures are a must. Of all the hazards that you’ll find present within your company’s buildings, electrical hazards are some of the most severe and common. Regardless of how apparent they are in your building, electrical hazards exist, nonetheless. Oversight of electrical problems, however, can lead to drastic damage and harm. Harsh electrical damage is typically avoidable with thorough safety assessments and preventative protocol. Preventative analyses and procedures are best when performed by professional electrical consulting engineers. Dreiym Engineering explores why you need a site walk-down inspection for your business infrastructures and what site walk-down inspections entail. To start, we’ll list the common causes of electrical damage in the workplace.

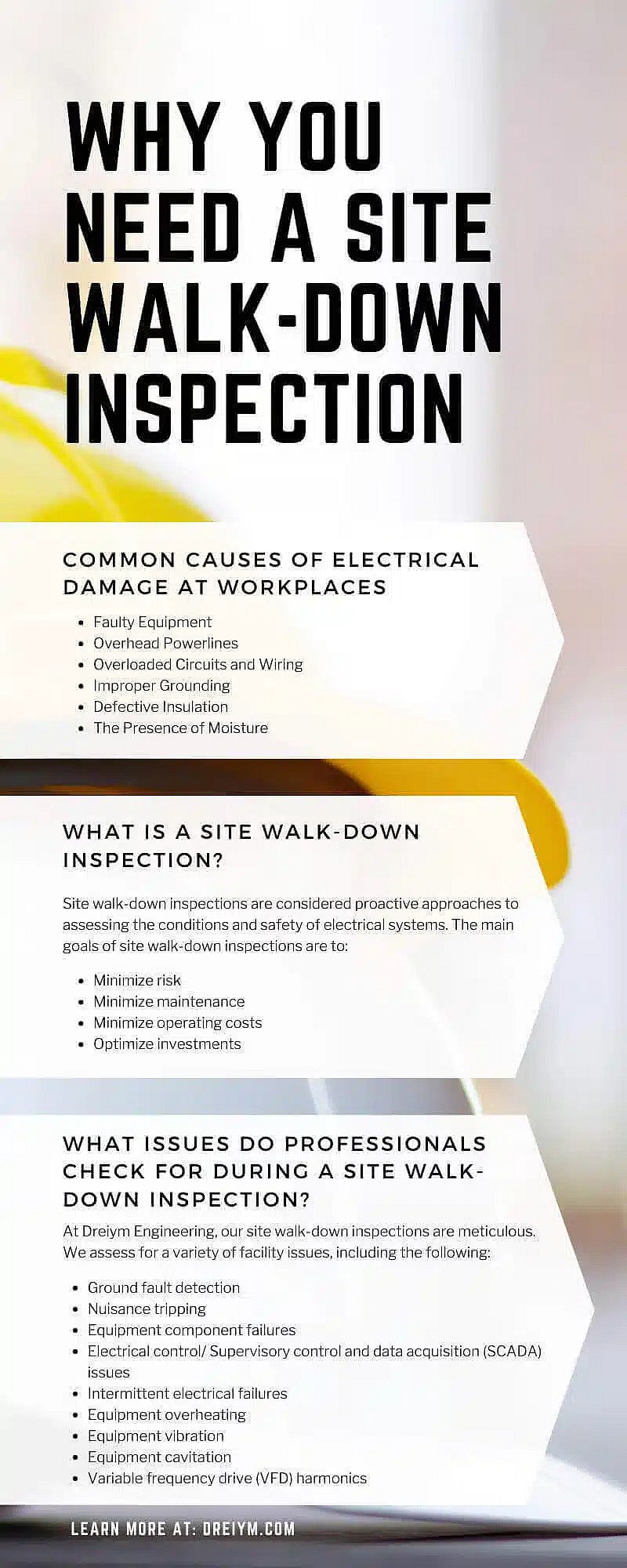

Common Causes of Electrical Damage at Workplaces

Although sometimes abrupt, electrical outbursts don’t occur out of thin air. Below, you’ll find various common causes of electrical damage at workplaces.

Faulty Equipment

When companies don’t keep their tools and equipment in good condition, these tools inevitably become dangerous to use. Without regular maintenance routines, employees become much more susceptible to electrocution since they’re unaware of when a piece of equipment is faulty.

You should always label defective electrical equipment and machinery as soon as you become aware of its condition. You should also remove the equipment from service instantly to prevent others from using it. Do not attempt to repair hampered electrical tools unless qualified to do so.

Overhead Powerlines

Overhead powerlines have impressive electrical currents coursing through them that can seriously harm employees if encountered. High voltages can leave serious burns and, in dire cases, cause death.

Enforcing a minimum distance from overhead powerlines and utilizing safety guards and barriers where possible can minimize any accidents with overhead powerlines.

Overloaded Circuits and Wiring

It’s crucial that your company and its employees limit electrical loads as indicated by electrical equipment. Overloading circuits, tools, and wiring is a surefire way to create a spark or even an explosion.

Inappropriately sized wires for a great electrical demand are a common cause of electrical fires. You should always invest in the recommended wires, extension cords, outlets, and connectors for each electrical tool to avoid overloading it.

Improper Grounding

To ensure that you’ve grounded your equipment properly, you should verify that your layout abides by OSHA’s grounding standards.

It’s likely that high voltage levels flow through the soil beneath your building. Improper grounding can result in unwanted exposure to voltage and increase the risk of electrocution at your workplace.

Defective Insulation

Hindered insulation is both an electrocution and fire hazard. Faulty insulation should be taken out of service immediately. Do not try to simply fix the issue with electrical tape and only reinstall once the wiring has been repaired or replaced.

The Presence of Moisture

Most people are aware of the negative relationship that water and electrical devices have with one another. The presence of water increases the chances of electrocution significantly. If electrical work must be done at a wet location, always be sure everyone on site is wearing adequate personal protective equipment.

What Is a Site Walk-Down Inspection?

Understanding what a site walk-down inspection is will make it a bit easier to understand why you need a site walk-down inspection for your company. Site walk-down inspections are considered proactive approaches to assessing the conditions and safety of electrical systems. The main goals of site walk-down inspections are to:

- Minimize risk

- Minimize maintenance

- Minimize operating costs

- Optimize investments

Those performing the site walk-down inspection strive to identify any existing electrical issues. They’ll also typically search for and locate the cause of these problems, letting the company know the best preventative methods to avoid causing or exacerbating issues in the future.

Because electrical systems are sensitive, especially those that are faulty, most businesses enlist the help of experienced electrical engineers to assess their systems. Engineers have the experience, protective equipment, and additional resources necessary to perform a thorough inspection safely.

What Issues Do Professionals Check for During a Site Walk-Down Inspection?

At Dreiym Engineering, our site walk-down inspections are meticulous. We assess for a variety of facility issues, including the following:

- Ground fault detection

- Nuisance tripping

- Equipment component failures

- Electrical control/ Supervisory control and data acquisition (SCADA) issues

- Intermittent electrical failures

- Equipment overheating

- Equipment vibration

- Equipment cavitation

- Variable frequency drive (VFD) harmonics

Relevant Types of Services Offered by Dreiym Engineering

Dreiym Engineering offers services separate from site walk-down inspections that also home in on electrical safety. Engineering design, ground surveys, and electrical coordination are also considered highly beneficial services for companies looking to maximize their workplace safety.

Engineering Design

Dreiym assists companies in creating and optimizing their electrical systems. Our consultants utilize their expert knowledge of regulatory standards and combine that with your company’s electrical expectations to create a system that’s well-running. Our engineering design services result in an electrical design system that also suits your specific operational needs.

Ground Surveys

Ground surveys help determine whether new installations meet grounding specifications. Ground surveys can also assess whether existing setups meet grounding requirements. A few different types of ground surveys that Dreiym offers include the following:

- Clamp-on readings

- Two-pin method

- Fall-of-potential method

- Testing of existing ground systems

- Cathodic protection interference

Electrical Coordination

Electrical coordination minimizes the impact that isolated failures can have on your entire electrical system. Without proper electrical coordination, your facility becomes vulnerable to a widespread power outage, which is incredibly detrimental to productivity and profitability. With proper coordination, a single load failure is stripped of the potential to cause a facility-wide outage.

Dreiym Engineering’s team of knowledgeable engineers strives to make your infrastructure as safe as possible. Optimizing building safety isn’t just pertinent to protecting employees; it’s essential to protecting your building from preventable damage, protecting your finances from violations fees and fines, and protecting your company’s name from a bad reputation. To guarantee that your infrastructure is getting off on the right foot or to identify the cause of various electrical issues at your workplace, contact Dreiym Engineering, PLLC today. With our assortment of inspections and analyses to choose from, you’re sure to feel more secure about your building’s safety after business with us.